News & projects

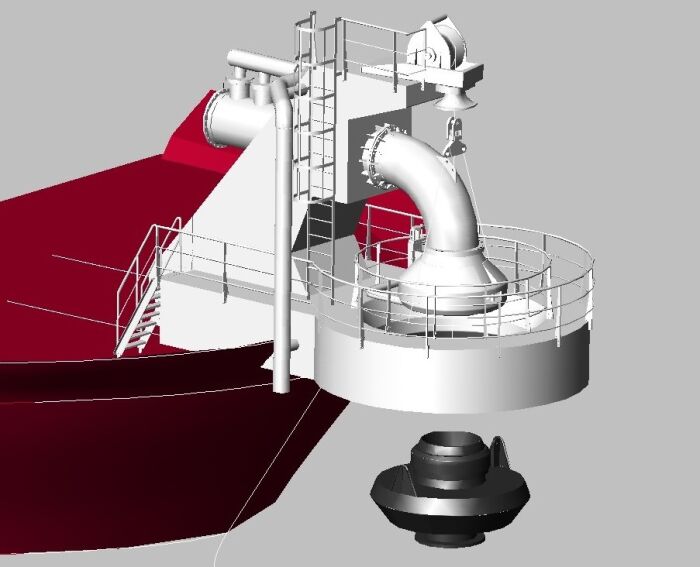

Engineering and production of bow discharge coupling

Straatman is currently working on a bow discharge coupling, which will be installed on an oil recovery and dredging vessel. We execute both engineering and production of this bow discharge coupling in our factory in Zwijndrecht. The unit, with an inside diameter of 900 mm, will consist of a fixed female part and a separate male coupling part with integrated floating body.

Read moreSolar powered Quick Release Hooks Port of Rotterdam

Straatman has been awarded to manufacture, supply and install 24 pcs of quick release mooring hooks including solar power systems for the new Ship to Ship berths along the Rozenburg peninsula in the Calandkanaal in the Port of Rotterdam.

Read moreWe developed a smart bollard with Port of Rotterdam

Along the quay of the Hutchison Ports ECT Delta terminal on the Maasvlakte, the Port of Rotterdam Authority has installed a smart bollard as part of a trial. The smart bollard was developed in collaboration with Straatman BV. By measuring the strain on the mooring lines in real time, the bollard not only allows the real-time monitoring of safety, but it also provides a clearer picture of which vessels can moor at which quays.

Read moreSolar power systems to power beam lights and nautical lights

With our extended experience in applying our Solar-powered and remote monitored systems, we can really provide for any situation. For this project, our customer has asked us to deliver a reliable, robust and durable Solar system to power a Beam light and, more importantly, a Nautical light in ATEX Zone 1 environment.

Read moreStraatman accepts order for bow discharge assembly

We are proud to inform you that we accepted an order for the production of a bow discharge assembly for a well known American shipyard. The bow discharge installation will have an inside diameter of ø762 mm and a maximum working pressure of 20 bar. Production of this 25.000 kg giant will start in 2021.

Read moreCapstans for safe berthing and mooring operations

We offer durable and cost-effective mooring solutions for the safe and efficient handling of mooring lines. In-house production and extensive guarantee.

Read moreQuick release hooks for mega cutter suction dredger

Sometimes you have a project that makes you aware again of all the possibilities of the products you make. These projects require all your in-house expertise to make the perfect product that meets the customers demand. The project we completed in our factory this week is such a project.

Read moreQuick Release Mooring Hooks for Malaysia

At the end of last year, one of our regular overseas customers requested an urgent quotation for a great project located in Johor, Malaysia. The specifications, issued by two independent consultants, had conflicting requirements which we had to list and highlight in our proposal.

Read moreDelivery of Capstans to HES Hartel Tank Terminal

Successfully factory tested, packed and ready for a delivery around the corner: This week we will deliver fifteen vertical capstans executed completely weather proof and suitable for ATEX Zone 1 to our customer HES Hartel Tank Terminal.

Read moreQuick Release Hooks order completed

At the end of last year, Straatman received a great order from a leading French civil contractor for the supply, commissioning and start-up of twenty four double 75 T Quick Release Mooring units which will be installed on three newly constructed ferry berths in Calais, France.

Read more