News & projects

Efficient In-hook Loadcell Calibration LNG berth Malaysia

Our recent project with Petronas involved the calibrating of the Mooring Load Monitoring Systems on their LNG Berth in Malaysia, equipped with Strainstall Quick Release Mooring Hooks.

In line with our takeover agreement with Strainstall three years ago, our engineers conducted a comprehensive inspection and verification of the current status of the Load Monitoring Systems. Post-verification, faulty load cells, and amplifiers were replaced to ensure the full berth was calibrated and operational again.

Read moreWe lead the way in mooring systems for LNG terminals

As the end of the year is approaching, it’s time to reflect. This year has been a remarkable journey for us as a company and as a team. LNG is the future of energy, and we are proud to be a part of it. We have completed mooring projects of the world’s biggest LNG projects, ensuring safety and efficiency in every operation.

Read moreBerthing Aid Systems for MET Terminal Rotterdam

In collaboration with Radio Holland, we have executed a project for the Maatschappelijk Europort Terminal (MET). We provided new Berthing Aid Displays, suitable for Hazardous areas, a new windsensor, and our MoorControl Software. We also repurposed existing lasers to interface with our new BAS displays.

Read moreVarious dredging equipment projects

These are busy days for dredging companies! At the moment there are many dredgers deployed around the world, and when the dredgers are doing their hard work at sea they require a lot of new equipment, as can be seen in our factory at the moment. We are currently working on several dredging projects for various well-known dredging clients. Read further to get an idea of the dredging projects we've been working on at Straatman the last couple of weeks:

Read moreQuick Release Mooring Hooks with so-called hauling-in trolleys

At Straatman, we have all the expertise to meet special requirements of our clients. We recently have manufactured multiple 60T Quick Release Mooring Hooks with so-called hauling-in trolleys for a client in India. These trolleys, designed, manufactured, and tested in our factory in Zwijndrecht, will be used to haul in ships on a dry dock for the Indian Navy.

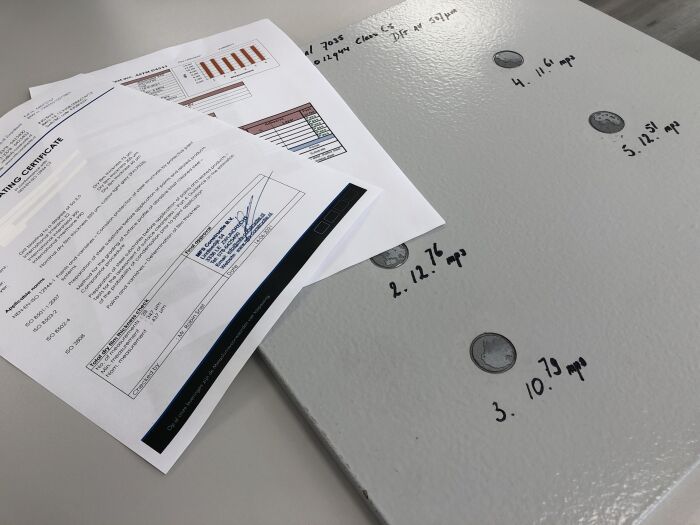

Read moreQuality control – adhesion test

At Straatman Dredging & Construction, everything revolves around the quality of our high-quality products and services. To check and demonstrate that the adhesion of a coating is good and therefore adheres properly to the product, we regularly carry out a pull-off adhesion test or so-called adhesion test. The adhesive strength of paint and coatings is a crucial element to give the material the basic functions of protection.

Read moreEnsuring Quality and Preventing Corrosion

To ensure the quality of our high-quality coating, we carry out various quality checks. One of the checks we can perform is the so-called Holiday Test. With the help of calibrated equipment, we check for small, invisible holes (pinholes) in the coating.

Read moreIncredible precision for construction special frames

Straatman Dredging & Construction is the right place for special machine frames where precision, accuracy, and tolerances are of high importance. We regularly build machine frames up to 30 m long for various clients.

Read moreMeet Straatman at LNG Shipping & Terminals Conference!

Our colleagues Prabjot Bains and Gertjan Strietman will be representing Straatman at the LNG Event in London, taking place from 14th to 15th November. Prabjot will also be delivering a lightning talk on the fascinating topic of Ship- to- Shore Link (SSL) on 15 November at 10:50 a.m. It will be a great opportunity for you to gain insights into this critical aspect of the LNG industry.

Read moreCommissioning Smart Bollard project at MSC Terminal Valencia

Our engineering team was in Valencia this week for the commissioning of Smart Bollards at the terminal which is dedicated to the world’s largest container shipping company, MSC.

Read more