Why a Smart Bollard?

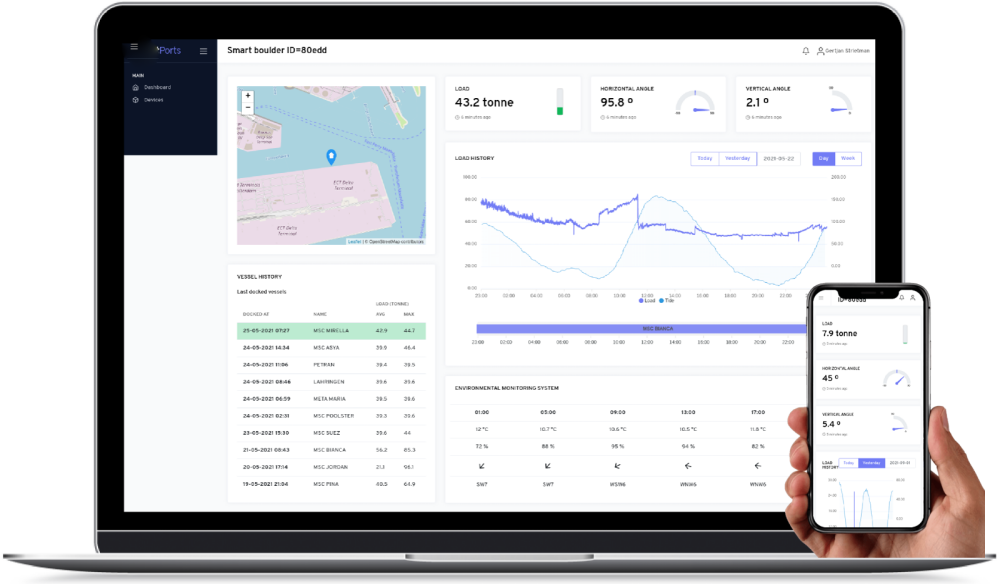

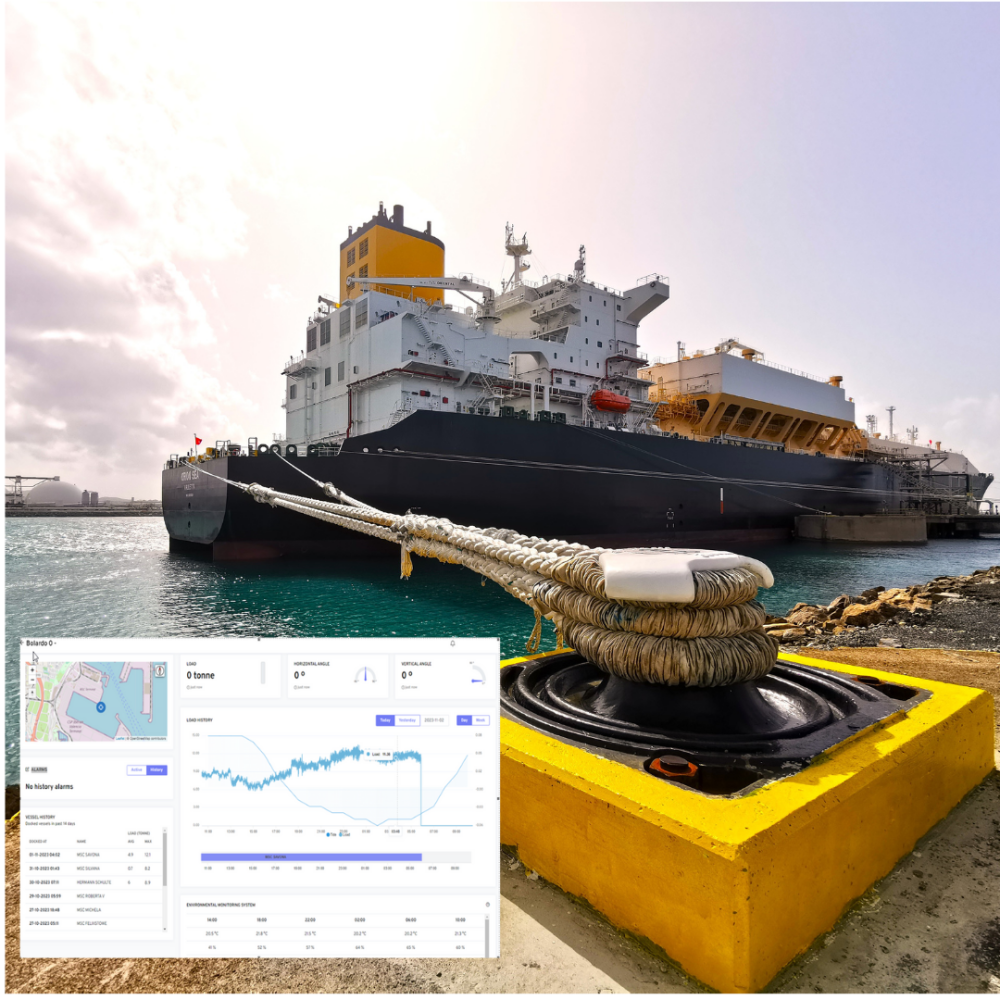

Until now it has not been possible to measure the load on mooring lines using a bollard. The lack of exact load data for moored vessels means that ports have to assume maximum mooring loads. For the Port Authority and Terminal Operator it is important to know exactly what the loads on the mooring lines are, especially in case of bad weather, with high waves, strong currents, and gusts. If the loads on the lines are too high the ropes can break and the ship will detach from the quay, which may cause serious accidents. The use of Smart Bollards can prevent this from happening. They increase safety by giving a real-time overview of the loads on the mooring lines, and provide a better understanding of overall mooring forces as data is logged.

In addition to this, the Smart Bollard can also help the terminal or port to improve efficiency with the loading and unloading of vessels. For port operations, a ship must be fully stable whilst moored. Loose mooring lines can result in excessive movement of the ship as a result of passing vessels or high winds. Any excessive movement of the ship can potentially result in crane operators damaging the ship during loading/unloading operations. By constantly monitoring the loads on mooring lines, operators, crew, and port staff can ensure the load remains constant, and the ship remains stable. This will inevitably result in smoother, faster, and safer loading and unloading of cargo.

The monitoring and data collection from the Smart Bollards will lead to more efficient port operations, and help to prevent unsafe situations from arising while vessels are moored.