Straatman Dredging & Construction is a specialist in coatings for the offshore and maritime sector. Preserving, painting, post-treating, protecting, or coating: These are all terms used for protecting (steel) products from external influences. Influences that damage the base material of constructions by causing corrosion and rust. Our coating work ensures your steelwork with a weather-resistant protective layer.

Wet painting, powder coating, and galvanizing

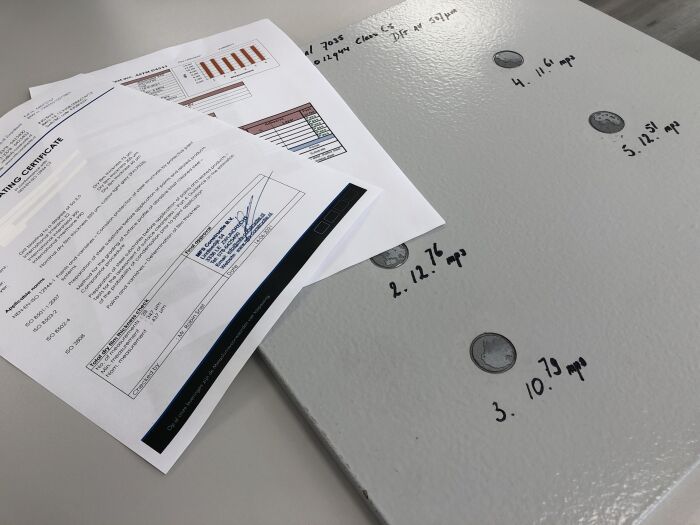

We provide coatings in our own workshop using wet paint systems and powder coat systems. With the help of our blasting cabin, conditioned wet paint cabin, and powder coat installation, we can take care of all finishes for your company. Also in accordance with the requirements of the maritime industry (ISO8503). In collaboration with our strategic partners, we also offer the possibility for electrolytic or thermal galvanizing.

Preparation is the key

At Straatman Dredging and Construction, we know better than anyone how construction parts need to be prepared, produced, deburred, and ground for a good coating. The quality of our coating therefore already starts at the sawing and drilling department, where literally every part of the construction is deburred and provided with the correct radius to guarantee good adhesion. Special parts are also blasted. At Straatman, we know better than anyone how construction parts need to be prepared, produced, deburred, and ground for a good coating. We can also carry out the preparation according to the ISO8503 standard.

Wet painting

Straatman Dredging & Construction provides your final product with wet paint in our special conditioned wet paint cabin. As the name suggests, wet painting is a coating technique where the paint layers are applied wet on wet. For optimal protection, this is always done in multiple layers, according to a so-called multi-layer system. Also for protection standards that are mandatory for extreme weather conditions in the maritime sector. Many of our clients come from the maritime sector. That is why we mainly apply wet painting in accordance with the ISO12944 standard up to the highest category: C5M (marine). For the 3-layer systems for this application, only high-quality paint systems from Hempel and International are used.

Powder coating

We use high-quality powders for our powder coatings, which meet the requirements of the construction industry. This is due to their excellent weather resistance and mechanical properties. Depending on the application, we select the powders, the number of layers, and the layer thicknesses. Just like wet painting, finishing with a powder coat is also possible in any RAL color.

We are specialized in various powder coating systems. Ranging from single-layer systems for steel to multi-layer systems for example aluminum. We can even make a distinction between applications for outdoor or indoor use. Straatman Dredging & Construction has powders in stock for various applications. This varies from powders based on epoxy resins to polyester resins and even combinations thereof.

The most extensive, or best protective variant is a so-called duplex system, in which steel parts are first galvanized and then powder coated. This is applied to products that are exposed to extreme weather conditions or are placed in a maritime climate.

Are you unsure about which coating system should be applied? Feel free to ask us for advice.

Recent Straatman Coating projects:

What to expect from Straatman Dredging & Construction

High Quality Products

Our products are designed and manufactured with attention to detail. We use the best materials and check everything to make sure you get the best.

Excellent Service Level

We’re here to help you. Our team is always ready to answer your questions and make sure you’re happy with our service.

Continuous Innovation

We always try to be better. We keep learning, improving and investing in research and development so we can give you the newest and best solutions.

Certified on Every Necessary Level

We meet all the important standards. This means our products are safe, reliable, and trustworthy.

Dedicated and Enthusiastic Team

Our team loves what they do. They work hard to meet your needs and make you happy.

We Do What We Promise

We keep our promises. You can trust us to do what we say we will.

Do you have any questions about our coating possibilities?

Use our contactform. We will try to answer your question within one working day.

Direct contact

Would you prefer to speak to someone directly? Our product specialists are ready for you every working day.