News & projects

The bow coupling, designed by Straatman

At Straatman Dredging & Construction, we don’t just make bow couplings – we invented them! In our Van De Graaf days, we introduced the first bow coupling, which has since become the global standard.

Our bow coupling enables a quick and efficient connection between hopper dredgers and floating pipelines, facilitating smoother beach and land reclamation operations.

Read moreStraatman Mooring Systems at Gastech 2025 in Milan

We are pleased to announce that Straatman Mooring Systems will participate as an exhibitor at Gastech 2025. This leading energy event will take place from September 9 to 12, 2025, at the Fiera Milano exhibition center in Milan, Italy.

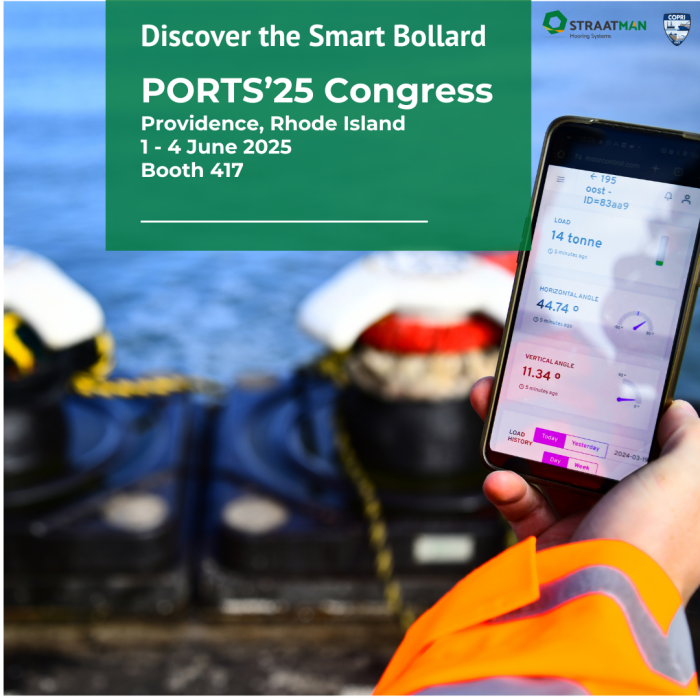

Read moreStraatman Mooring Systems will be at PORTS' 25, USA

We are happy to announce that Straatman will be an exhibitor at the PORTS'25 Conference in Providence, USA, from June 1-4, 2025. This international event focuses on port and harbor development and is a great place to learn about the latest innovations in the industry.

Read moreStraatman wins innovation in safety award with Smart Bollard

Wow, we are so proud! Straatman has won the Innovation in Safety Award in London for our groundbreaking Smart Bollard!

This prestigious award, presented at the ICHCA / TT Club event, recognizes our commitment to enhancing safety and efficiency in mooring operations. It is a testament to our dedication to developing solutions that improve port and terminal safety worldwide.

Read moreExperiencing downtime due to mooring issues?

Regular maintenance is key to extending equipment lifespan and preventing costly failures—especially in harsh marine environments.

We specialize in inspecting and maintaining quick release mooring hooks and related equipment from all major brands, including Strainstall and AMTS. Our experienced team provides on-site servicing, repairs, spare parts, upgrades, and tailored maintenance contracts. We help extend your equipment's lifespan and reduce costly downtime.

Read moreReviving Ship-to-Shore Links: A successful upgrade

We recently completed a challenging project: Replacing an outdated Ship-to-Shore Link (SSL) system for an LNG Carrier under a tight deadline. The client’s old system, including 6-pin Fibre Optic, 37-pin Pyle and 6-pin Miyaki Electric links, was no longer supported, and spare parts were unavailable.

Read moreFrom bow couplings to ball joints

At Straatman Dredging & Construction, we specialize in high-quality dredging couplings. From bow couplings to ball joints, our factory has run at full speed to support dredging projects worldwide. Here is a look at what we have delivered recently and what is currently in progress.

Read moreInnovation in dredging: the evolved Straatman bow coupling

We're proud to share our latest upgrades by introducing our new design bow coupling. This ø900 male part, recently delivered to DEME, has proven its reliability in the ø1000-30 Bar bow couplings and is now applied to the 900 series.

Read moreAnother Great SSL Project for Straatman Mooring Systems!

We’re pleased to see our SafeCom Ship-to-Shore Link (SSL) in action onboard the Energy Stockholm, Europe’s largest inland LNG bunker vessel, built in 2023 in Turkey and inaugurated in November 2024 in Rotterdam.

The Energy Stockholm has a cargo capacity of 8,000 m³ and operates in major ports like Rotterdam and Antwerp, fuelling various vessels.

Read moreDelivery of SafeCom SSL

Two Small-Scale SafeCom Ship-to-Shore Link (SSL) systems are heading to a client in South America, equipped with 5-pin SIGTTO connectors. Designed for both terminal and Floating Storage Unit (FSU) sides, these systems ensure seamless and secure oil and chemical transfers.

Each SSL system comes with smart pushbuttons and an intuitive interface, enabling easy operation and smooth switching between supplier and receiver modes. With compliance to SIGTTO standards, the 5-pin connector guarantees reliable ESD signal communication between vessels and terminals, enhancing safety and efficiency.

Read more