News & projects

Hands-on training mooring equipment

Upon the initial vessel's arrival, our service engineers revisited the multiple terminals where our mooring equipment was recently installed. Their objective is to ensure the smooth integration of our equipment and to provide comprehensive hands-on training to terminal operators. This direct, onsite training is essential for equipping operators with the knowledge and skills necessary to handle the equipment safely and effectively. By empowering operators to identify and address potential challenges independently, we enhance operational efficiency and reduce reliance on external support. This proactive approach not only fosters a sense of confidence and competence among operators but also contributes to the overall reliability and performance of our mooring systems.

Through diligent oversight and targeted training initiatives, we remain committed to delivering continuous service and support to our clients, ensuring the seamless operation of their terminals.

Read moreUrgent delivery of mooring equipment to terminal in Germany

End of November we were called by a German client as they were facing a problem at the LNG terminal in Brunsbüttel. This terminal is located in the North of Germany, along the Elbe river, close to Hamburg. The client had several mooring hook units which have been rejected after an inspection. With a ship coming in within a few weeks, Straatman was asked to deliver new triple Quick Release Mooring Hook units in just three weeks.

Read moreComplete FSRU Mooring system for LNG terminal Finland

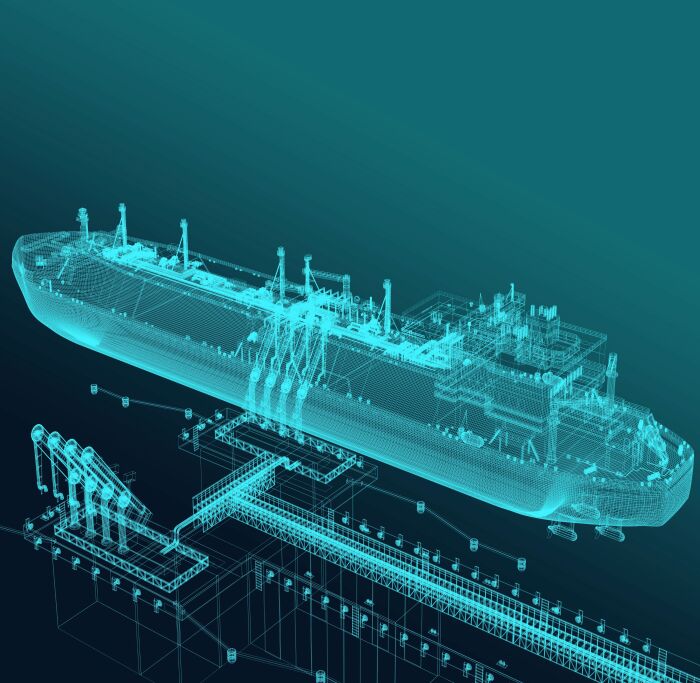

With the coldest part of the year kicking in, our team of engineers keep on rocking! In the cold and harsh environment of wintry Finland, we commissioned the complete mooring system for a newly built floating LNG terminal at Fortum’s Inkoo port, which is located at the Southern coast of Finland.

Read moreMooring equipment LNG terminal Wilhelmshaven Germany

Last week we commissioned the complete mooring system for Germany’s first FSRU-based LNG Terminal, located in Wilhelmshaven in the North of Germany along the North Sea coast. The terminal will facilitate LNG import into the European market. Mid-December, the first FSRU can be docked.

Read moreMooring system for LNG terminal Paldiski, Estonia

The complete mooring system for LNG terminal Paldiski in Estonia is commissioned last week and ready for use.

We are incredibly proud of the Straatman team! This project had a very challenging time scheme, as the LNG terminal needed to be operational within 6 months.

Read moreStraatman mooring equipment LNG terminal Paldiski.

In cooperation with our local representative, Straatman accepted a fantastic order for LNG terminal Paldiski in Lahepere Bay in Estonia. Since the terminal needs to be operational in Q4-2022 the delivery time was one of the main selection points of the local contractor. As Straatman still manufactures most of the parts in-house, we are able to meet this very challenging time schedule.

Read moreOur mooring and dredging expertise combined

A couple of years ago we used our expertise to design remotely operated 250 tons quick release hooks, equipped with a solar powered hydraulic powerpack. These are used by a mega cutter suction dredger on their left and right anchor line pontoons, for safe deployment and operation. The lines are used to move the ship in a left-to-right motion, sweeping their dredging work along the sea or river bed.

Read moreStraatman and Strainstall collaboration celebration

After 9 months of working virtually, it was great to meet in person at last!

Straatman and James Fisher Strainstall celebrate the first nine months of our relationship in servicing Strainstall’s legacy quick release hook customers. Due to Covid restrictions all contacts between Strainstall and Straatman have been online until last week, when we finally met in person.

Calandkanaal mooring project ready for installation

After a lot of hard work in the last months of last year, we are happy to inform you that we have successfully completed the assembly and testing of the 24 ATEX and Safe Area solar systems for the expansion of the berths 81 and 82 in the Calandkanaal, Port of Rotterdam. All systems were completely tested in our factory to ensure a smooth and efficient installation on site coming April 2022.

Read moreDynamic Positioning Optimization using quick release hooks

For several years, our customer McDermott have been using our custom designed quick release mooring hooks on their pipelaying vessels.

Read more