From request to delivery: what does a quick release hook custom project entail?

How does a custom project come about?

It is important to know that the quick release hook is our basic product and can be modified to suit your needs. The customizable aspects of quick release hooks are very comprehensive and exceed more than color, size and type of hook. Tell us about your plans and the purpose of the hooks, so that we can define the required adjustments.

How do we convert your issue, question or case into a custom product?

After we've received your request, we will contact you to hear about more details, your budget, and other specifications or desires. If needed, we will call you, invite you over or pay you a visit. We will then do the calculations and write a bid proposal. We believe that good communication plays an important role in successful custom projects.

What does the duration of the project depend on?

The duration of the project does not only depend on the variables of the quick release hook, but also on the engineering and on the location of implementation. Depending on the complexity and scale of the project, we can deliver a final custom project within 4 - 5 months.

What can you expect from us?

You can count on us to live up to what we say. We have a no-nonsense mentality and will keep you up to date on the progress and status of our project. We are not afraid to contact you if a problem arises or if we experience a delay. Furthermore, we're experienced in what we do and aim to customize products that exceed your expectations. Moreover, we've got all the tools, engineers, and knowledge in-house. We have everything under one roof, meaning that we can assort, calculate and draw up all projects. You are more than welcome to come to our workshop in Zwijndrecht and watch our production processes. This will help to make our collaboration more tangible for you.

Custom project case: DP Optimization by using quick release hooks

Our client McDermott owns several pipelaying vessels. These vessels are all fitted with a Dynamic Positioning System (DP) to hold their exact location during operation. This location is critical for pipelaying, as the pipes need to be installed in one exact position on the seabed. During one of McDermott's projects with their Lay Vessel North Ocean 105, they experienced heavy weather conditions. The DP had to run on full capacity but it was almost impossible to hold location. Quitting was not an option, so they had to use tugboats to assist them. This worked out, but the external pulling force from the tugboats to hold the vessel's position created several alarms in the DP system. The added force by the tugboats couldn’t easily be handled by the DP software, as this “external force” did not match the measured values on the DP.

The onboard engineers came up with a solution to solve this for the future. This solution entails registering the pull of the tugboats and integrating these values into the DP. The DP software can then calculate its position and required operation by using the loads in the lines to the tugboats. The best way to measure the load on a line is to use a quick release mooring hook, fitted with a load cell. This hook can be used to release the line in case of emergencies as well.

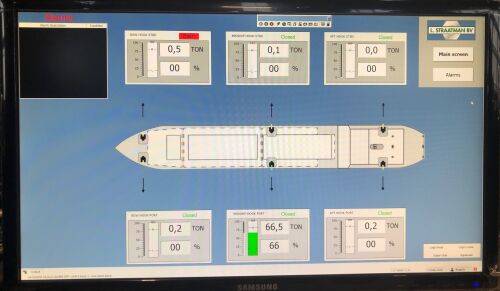

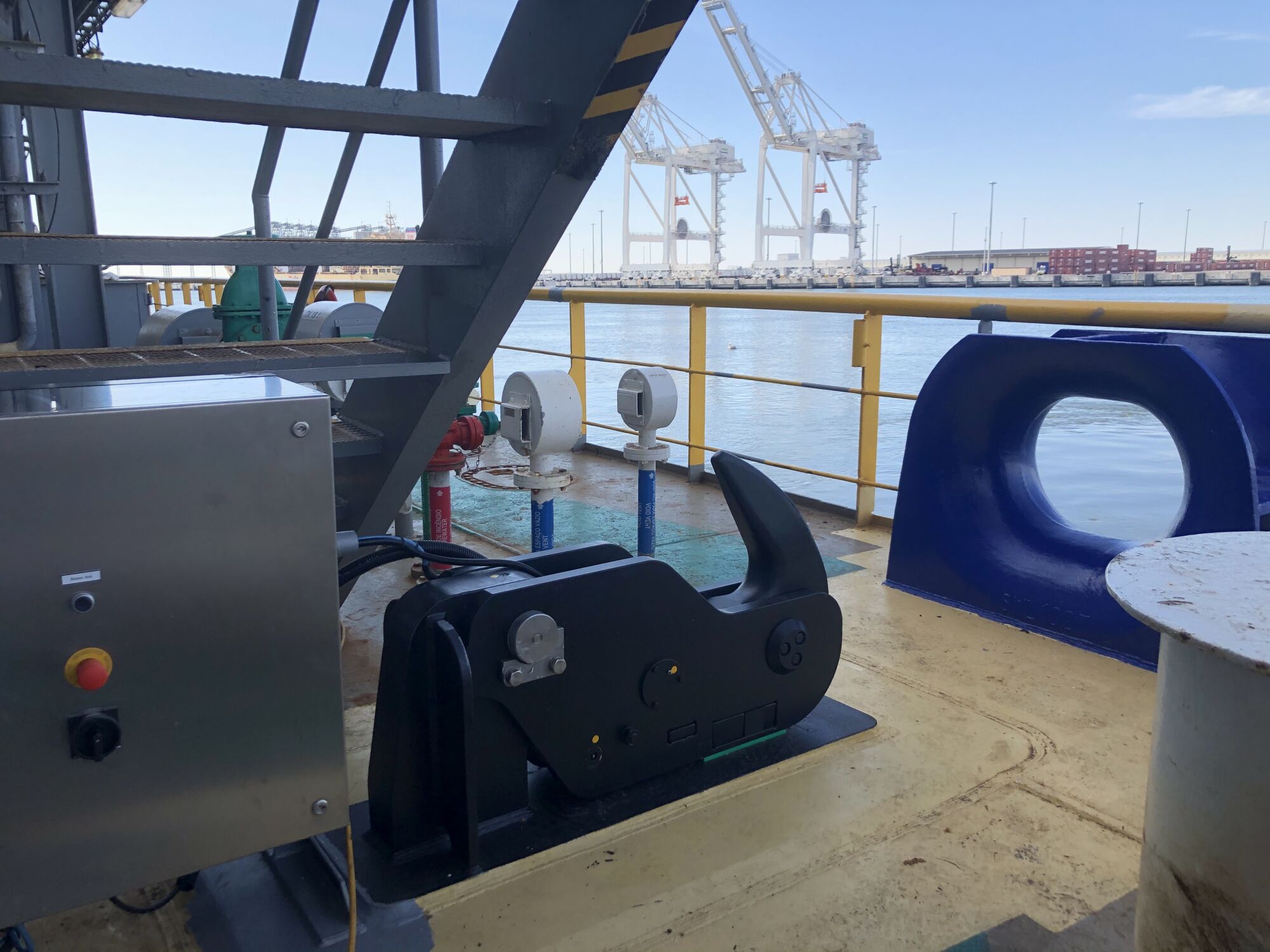

Straatman was consulted to design a special hook foundation to fit six quick release mooring units on different locations of the deck of the vessel. This creates a connection between the newly installed Panama Chocks and the tugboats. The quick release hooks itself are fitted with load cells to measure the exact load on the lines. With the Straatman mooring software, these loads are easily displayed on the PC on the bridge. The system is connected to the DP, where the loads are used to optimize the system and operate smoothly. Besides the load monitoring system, they can release the hooks remotely in case of emergencies, by using our electric release system.

Get in touch

Are you experiencing similar problems with your DP? Contact us directly or via one of our agents around the world. Please consult one of our specialists about Straatman's quick release hooks. You may also request a bid proposal for your project via email. Or better yet: come find us at one of the offshore technology trade fairs.

Do you want to know more about our services and products?

Please contact us, we will tell you more about it! Fill in your details below. We aim to give you a response within one working day.

Would you prefer to speak to someone directly?

Our product specialists are ready for you every working day.