‘In-house production is the only option if you want to guarantee quality’

Machine factory Straatman is the only producer of Quick Release Mooring Hooks in the world with its own in-house production facility. Sales Manager Maarten Verboom is very adamant about this: ‘If we want to be the market leader in Quick Release Hooks, safeguarding the quality will always be our key concern and this means that, for us, in-house production is the only option.’ To demonstrate this conclusion, Straatman takes us on a tour of the production process. Read this article and discover the unique advantages Straatman offers against a very competitive price.

Machine factory Straatman is the only producer of Quick Release Mooring Hooks in the world with its own in-house production facility. Sales Manager Maarten Verboom is very adamant about this: ‘If we want to be the market leader in Quick Release Hooks, safeguarding the quality will always be our key concern and this means that, for us, in-house production is the only option.’ To demonstrate this conclusion, Straatman takes us on a tour of the production process. Read this article and discover the unique advantages Straatman offers against a very competitive price.

Design and engineering

In the late 1980s, Straatman (at the time still called Van de Graaf’s Werktuig-en Constructiebouw BV) manufactured the first Quick Release Hook. Since that time, they designed hundreds of hooks in all sorts and sizes. This has resulted in an extensive catalogue which offers a wide variety of options for the hooks. It does not happen very often that a client has very specific, new requirements, but every new hook is often still made with a unique combination of parts. This is why each hook starts its life at Straatman’s design department. We are a few weeks into the process now and, so far, Straatman’s approach does not differ very much from its competitors…

Production of Quick Release Hooks

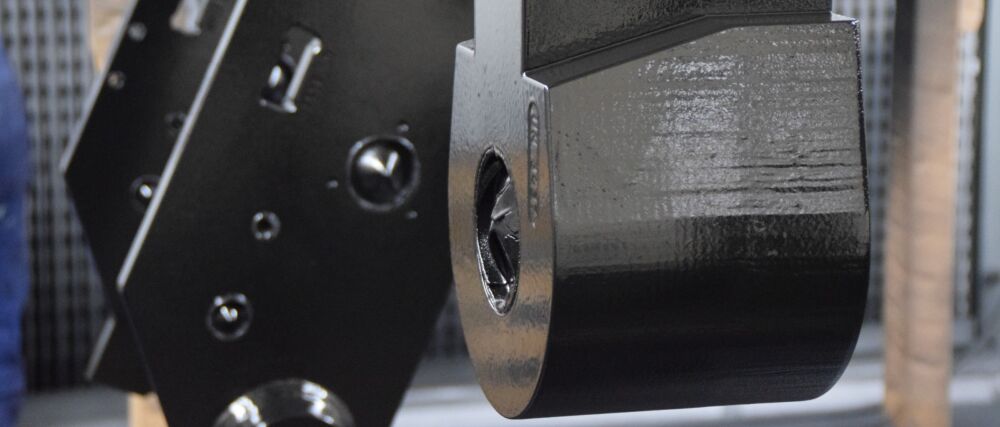

It is when we enter the production hall that we get a real impression of the size of the operation. All semi-finished materials, such as steel plates and machined parts, are all neatly labelled and bundled together. Production Manager Gideon Höhle explains: ‘For the critical parts we only work with materials originating from Western Europe. The quality control here is organised very well and we know exactly where all materials come from. These companies have their quality systems in order, which are also clear to us. When selecting our suppliers, this is one of our focal points.’

"we know exactly where all materials come from.."

The various steps in the process also make it clear that control is very important to Straatman. Since a number of years, the coating of the products has also been an in-house process. Gideon: ‘With the increasing quality demands in, for example, the offshore industry, having a dedicated coating process is essential.’

Testing

Even so, Gideon’s pride and joy is the Quick Release Hook test machine. Ever since the first hook was produced, each hook is tested on Staatman’s specially designed test bench. ‘It is still amazing to show the quick-release mechanism at a release load of 250 tons. Every single time, clients take out their mobiles to film the testing process’, Gideon tells us with a smile. ‘I notice that clients are really impressed with how tightly organised our processes are, and how transparent we are about it. This is one of the aspects with which we like to distinguish ourselves, and that is why we hold on to in-house production. It is the only way.’

Do you want to know more about our services and products?

Please contact us, we will tell you more about it! Fill in your details below. We aim to give you a response within one working day.

Would you prefer to speak to someone directly?

Our product specialists are ready for you every working day.