What is a Smart Bollard?

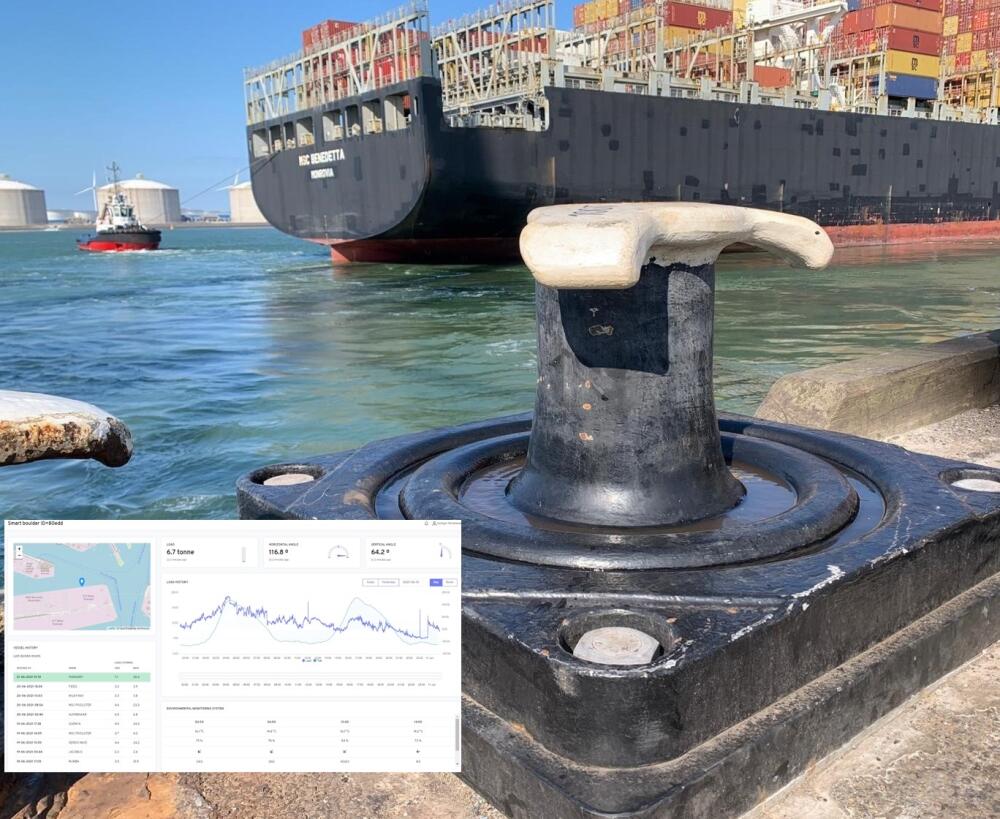

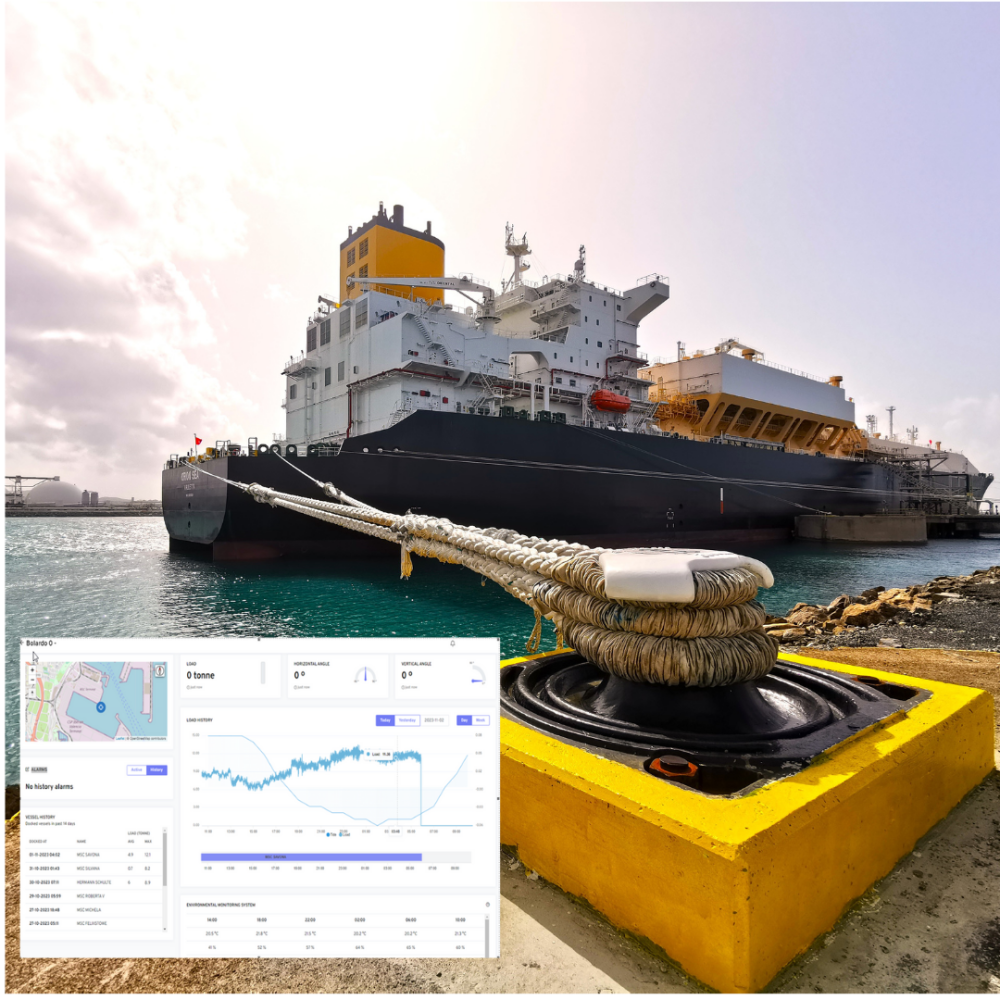

A Smart Bollard, although reminiscent of a traditional ship bollard or dock bollard, brings cutting-edge functionality to port operations. It is permanently affixed to quays but stands apart with its ability to measure load on mooring lines. This bollard detects and quantifies structural movements induced by the tension of the mooring lines. The ensuing data becomes accessible to the port authority, terminal operator, or even the vessel itself. In essence, the Smart Bollard enhances the safety and efficiency of docking for a variety of seagoing vessels, from container ships to bulk carriers.

Why a Smart Bollard?

Traditionally, the load on mooring lines, such as those attached to bollard docks or loading dock bollards, couldn't be precisely measured. Ports would often assume maximum mooring loads due to this data void. Accurate insights into mooring forces become particularly essential during adverse weather conditions characterized by high waves, strong currents, and gusts. Overburdened mooring lines risk breakage, potentially resulting in ships drifting away from the quay and causing significant accidents.

Smart Bollards rectify this by providing real-time data on mooring line loads. Coupled with the advanced MoorControl software system, stakeholders, from the Terminal Operator to the Port Authority, receive lucid information on mooring forces. This enhances port efficiency, especially as vessels grow larger and weather becomes more unpredictable.

Monitored data from Smart Bollards paves the way for streamlined port operations, reducing risks during vessel mooring.

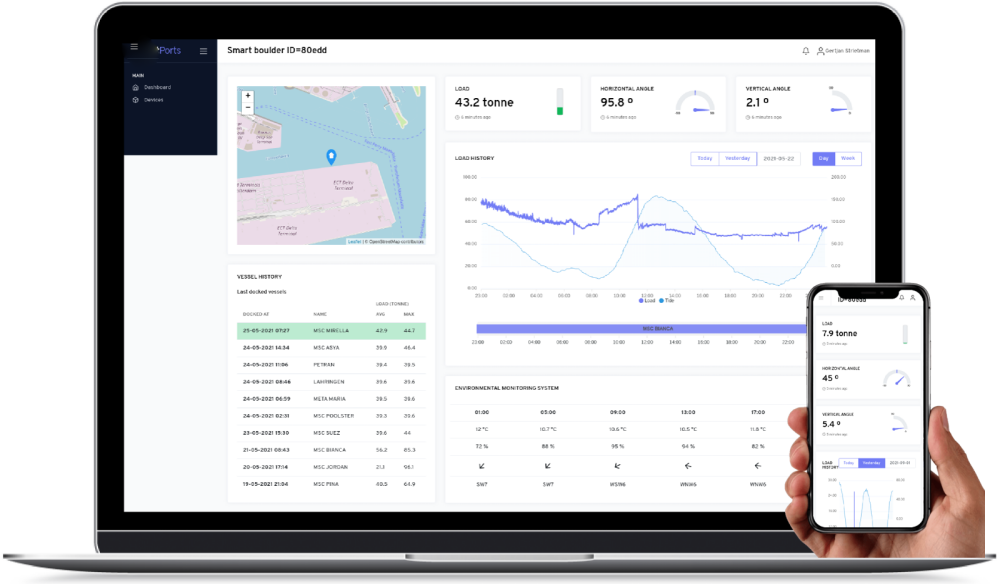

An intuitive dashboard provides:

- Load on the bollard

- Line direction and angle

- Tide levels

- Weather data

- Vessel history (AIS data)

An accommodating interface permits easy user additions and alarm settings. Moreover, the integrated API ensures data accessibility, beneficial for the Port Authority, terminal operators, and vessel operators.

Benefits of the Smart Bollard

The Smart Bollard offers myriad advantages:

- Safety: Real-time monitoring bolsters safety measures, predicting forces and providing real-time load data.

- Efficiency: By presenting a holistic view of mooring forces, vessel movement becomes more efficient.

- Port Capacity: Insights into quay capabilities might facilitate mooring of even larger ships.

- Resource Optimization: Accrued data and predicted forces could lessen the need for cost-intensive resources like tugs.

- Data Utilization: Accumulated data can inform port enhancement projects and the ongoing refinement of operations.

Data connection of the Smart Bollard

The Smart Bollard can either be connected via ethernet or operate wirelessly. Ethernet connections necessitate a separate switchbox for data transmission to the cloud, whereas wireless operations require an onsite gateway installation. of an on-site gateway.

Cloud and API

Transmitted data is hosted on the AWS cloud, accessible through a dedicated portal. This portal also offers weather and current data and can house a vessel database. Its standard API ensures effortless integration with other systems.

Do you want to know more about Smart Bollards?

Contact us and we will get back to you. Our product specialists are ready for you every working day.

Trial at Port of Rotterdam

Straatman, in collaboration with the Port of Rotterdam, pioneered the Smart Bollard concept. As part of a trial, the Port of Rotterdam introduced the Smart Bollard at the ECT Delta Terminal. This move aligns with the port's digitization drive aimed at enhancing efficiency. The subsequent phase entails a broader installation of Smart Bollards across the Port of Rotterdam's quays and other ports around the world.

Download here our Smart Bollard brochure

Related blogs

Learn more about our Smart Bollards

Use our contactform. We will try to answer your question within one working day.

Direct contact

Would you prefer to speak to someone directly? Our product specialists are ready for you every working day.